How In-line Process Refractometers Improve Beer Production

Beer Brewing is a fine art cultivated by those who have spent years meticulously refining their craft for the perfect delicious ale. But where does art meet science in achieving and keeping perfection?

With various touch points of the brewing process, liquid concentration can be an integral factor in changing the quality and profile of your beer, and manual sampling refractometers may not quite hit the mark when needing to measure consistently, not to mention potentially introducing unwanted bacteria or wild yeast into your production.

The Vaisala K-Patents and Polaris in-line process refractometers are the answer for measuring liquid concentration at all stages of the beer brewing production, from measuring the concentration of mash, lautering, boiling, whirlpooling, cooling, fermentation to filtration and maturation.

Why is constant Liquid concentration measurement in Beer Brewing Important?

Foremost to support the quality and profile of the beer, but other benefits include giving instant and useable insight into raw material management and overall sustainability of resources in our production line. Traditional manual sampling methods require opening up production to retrieve a sample and taking Brix measurements from a handheld refractometer, though typically used in smaller beer production installations, this method increases the risk of introducing wild yeast into the production - and at scale this can be detrimental to a production run.

The Vaisala Inline Process Refractometers allow beer production teams to monitor brix in real-time allowing for adjustments to be made quickly, preventing waste and saving on raw material.

How does an inline process refractometer work?

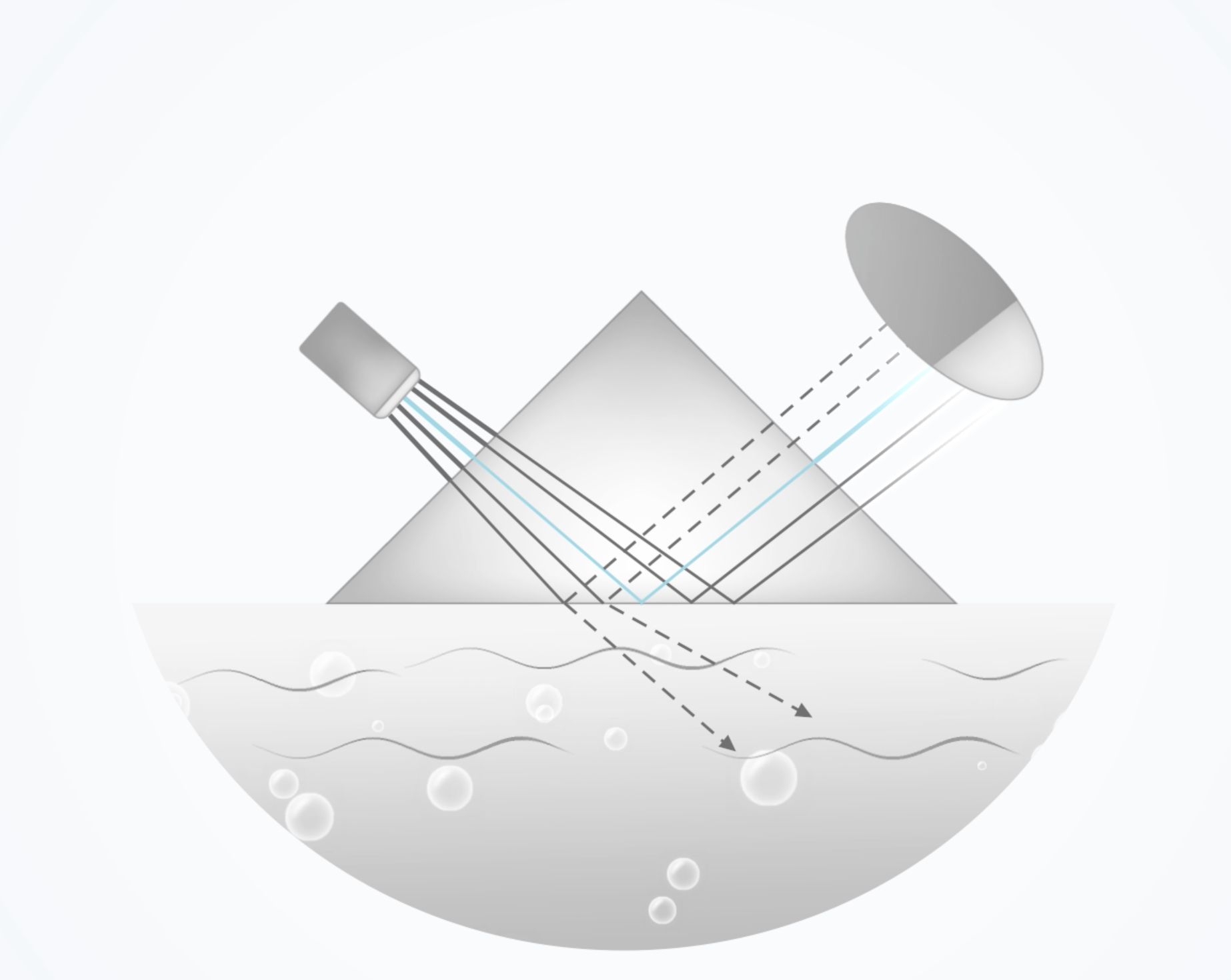

The Vaisala K-Patents and Polaris Inline Process Refractometers are made up of three modules, a light source, a prism, and an image processor, all encased within a stainless-steel body that sits within the water output of each stage of the brewing process.

To produce a measurement, the light is produced to shine through the prism, which depending on the concentration of liquid, the light will refract into the liquid and the remaining light will be reflected into the image processor. This principle of measurement is called "The Critical Angle of Measurement".

How does it fit into my application?

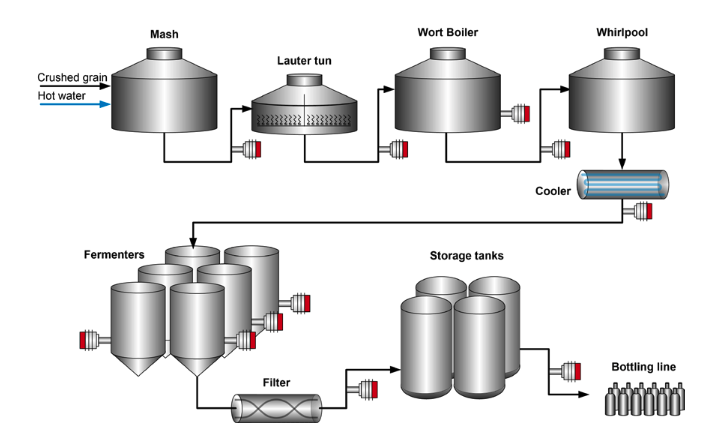

As you can see in the diagram below, inline process refractometers can be installed at essentially all stages of the brewing process, however, the type of measurement may vary depending on the stage, such as measuring Brix, gravity, density or Balling. It's also worth noting that different stages of the brewing process may require different types of inline process refractometers, such as boiler and heated stages may require the use of PR53-AP Sanitary Probe Process Refractometer, and fermentation, filtering and storage stages may require a PR53-AC Sanitary Compact Process Refractometer.

Benefits of Using an Inline Process Refractometer

- This measurement system is unaffected by particulates, media or bubbles within the liquid, only influencing factor is the density of the liquid.

- Greatly reduces the introduction of wild yeast and foreign bacteria due to inline installation.

- Constant monitoring identifies where efficiencies can be made, reducing over-expenditure and waste on raw materials and production.

Would you like to know more?

The Vaisala Inline Process Refractometers can be used throughout various industrial food and beverage applications, from beer production and soft drinks to juice and dairy production. The ADM Instrument Engineering Team are here to help with any questions you may have about finding efficiencies within your food and beverage production. Contact us here.

The Vaisala Process Refractometer range has decades of success in providing many different industries with live real-time constant monitoring, tailoring different process refractometers to the different industrial needs. You can view the Vaisala Inline Process Refractometer range here.