MEAN WELL VFD Series: Enhancing Motor Efficiency

As we strive towards a more sustainable future, the topic of energy consumption has become a global issue of concern.

With consumers facing high energy costs, demand for energy-efficient appliances that offer lower environmental impact is ever increasing. According to IEA, around 40% of electricity is consumed by industry worldwide, with the largest single-energy end use from electric motors used in pumps, compressors, conveyors and handling systems. Variable speed drive technology offers a unique advantage in helping reducing energy consumption without hindering operational performance.

The Efficiency of VFDs

Variable Frequency Drives (VFD’s) are designed to allow for accurate motor speed control by varying the frequency and voltage of its power supply. Traditionally, motors often run at full speed regardless of the actual demand, leading to unnecessary energy consumption. VFDs, on the other hand, allow motors to operate at the optimal speed required for the task, minimising energy usage and reducing utility bills.

In terms of motor compatibility for VFDs, there are two types of commonly used DC motors: brushed motors, and brushless motors (or BLDC motors). BLDC motors are favoured for their efficiency and longer lifespan compared to three-phase induction motors. As the name suggests, brushless DC motors do not have any brushes to cause wear. The motor produces minimal audible noise and maximum efficiency which are ideal for applications needing long life and precise control. By moving to energy-efficient motor brushed controllers with variable frequency control, electrical usage can be significantly reduced.

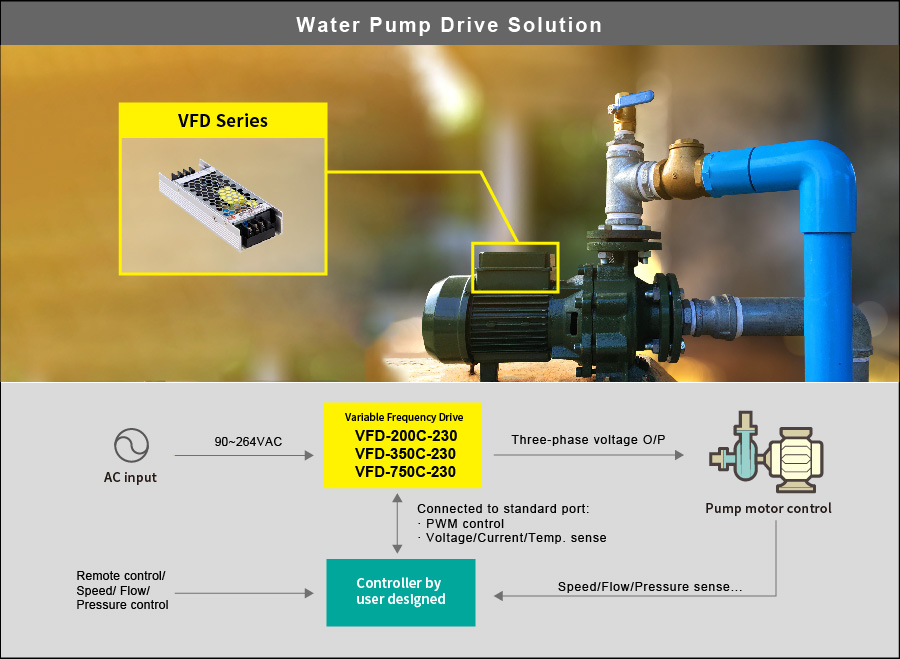

MEAN WELL VFD Series

Whilst BLDC motors prove to have a high efficiency and better controllability that optimises system operations, the design complexity and cost often deter adoption. MEAN WELL developed a series of variable frequency drives for applications that utilise BLDC motors – the “VFD series”. Comprising of eight models that cover both DC and AC input voltages, the VFD series features an in-built PFC function, with power ratings ranging from 150 to 750W. The drive has a fanless design, ensuring noiseless operation with maximum efficiency of up to 93% and peak current of 200%.

Complying with international safety standards IEC/EN61800 -5-1 and electromagnetic compatibility standards IEC/EN61800-3, these VFDs are suitable for end devices and products that use brushless DC motors such as fans and AC systems, smoke extraction equipment, water pumps, automated guide vehicles (AGVs), power tools, automatic doors, mechanical equipment, conveyors, medical devices, fitness equipment, etc.

If you have any questions about how the MEAN WELL VFD Series might be suited for your needs, the ADM team is here to help. Call on 1300 236 467 or send us your enquiry here.