Eurotherm Process Control & Data Acquisition

Process control and data acquisition are cornerstones of scaled production. They enable a standardised process that delivers consistent quality daily while collecting data to build efficiency and securely store data for compliance.

Scaled production typically consists of layers of systems, ranging from programmable logic controllers overseeing larger groups of systems, and proportional integral derivative controllers focusing on specific aspects within the production process

Data acquisition runs parallel to the process. It is tasked with collecting key information from various aspects of the production process and securely storing it within an encrypted system. Data acquisition systems play a key role in determining better efficiency in the future and safeguarding quality control for compliance purposes.

In this article, we’ve broken down the various aspects of Eurotherm products and how they support process control and data acquisition for any production process.

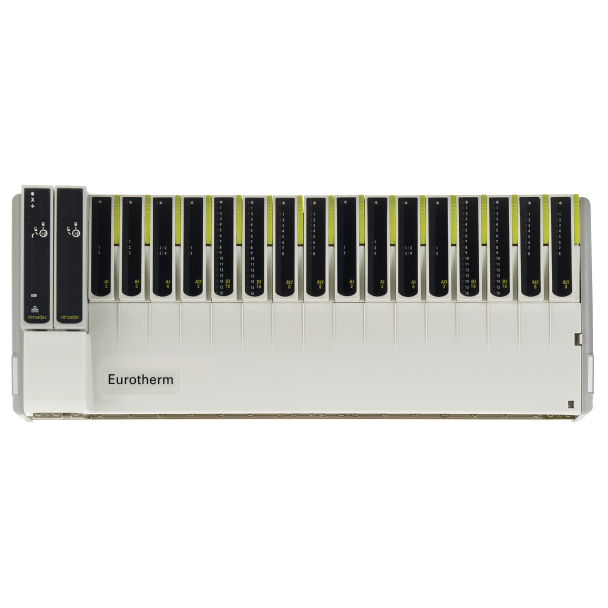

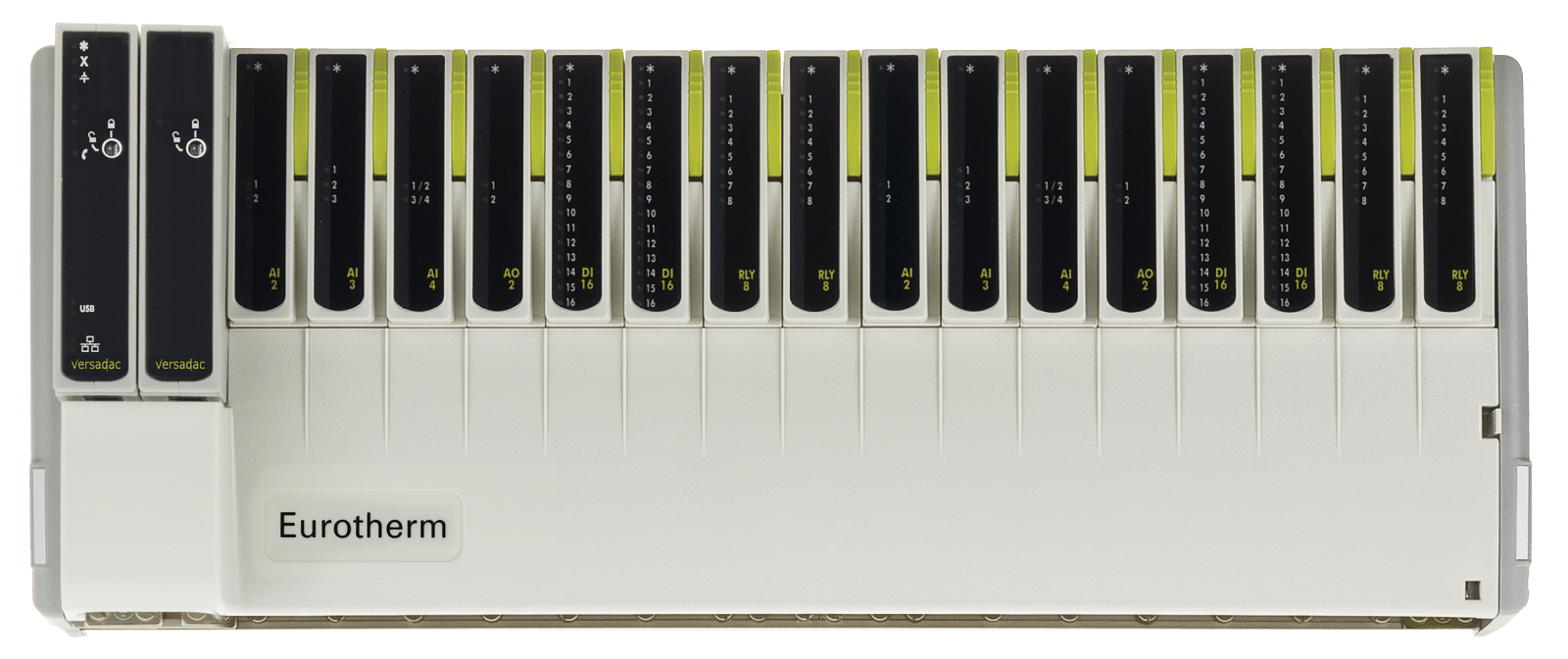

Programmable Logic Controllers

Programmable Logic Controllers are typically found as an overseeing control system within an industrial automated process. Programmable Logic Controllers (PLCs) are fundamentally designed to be discrete control systems comprised of a limited number of states for inputs and outputs. For the most part, PLCs effectively operate under a set of on and off states.

There are often two different types found in operation:

- Fixed/Integrated/Compact PLC

- Modular PLC

Fixed/Integrated/Compact PLCs often have a fixed range of input/output options. The Modular PLC allows users to add or reduce the range of input/outputs as needed.

PLC controllers commonly oversee larger industrial automated systems, with many stages. For example, a bottling plant encompasses many tasks, from filling bottles, applying labels, and packaging into boxes. Each stage of the plant provides a yes or no response to the PLC, allowing or disallowing the process to progress to the succeeding stage.

Products in this range:

Proportional Integral Derivative Controllers

Proportional Integral Derivative controllers take a granular approach, focusing on a specific segment within a process to ensure a consistent result. PID controllers do this by taking feedback from sensors, such as thermocouples, and adjusting the process to ensure the programmed setpoint parameters are met with each batch.

Products in this range:

- Nanodac

- Eurotherm Mini8

- Eurotherm EPC3000 Series PID Controller

- Eurotherm EPC2000 Series PID Controller

- Eurotherm 3500 Series Duel PID Loop Controller

Process Automation Controllers

The Process Automation Controller may provide the ideal combination of PLC functionality and high-accuracy PID Loop Control. It also includes coverage with redundant central processor units, various programming languages, and the ability to incorporate advanced control strategies.

Products in this range:

Data Acquisition:

Though primarily used for quality control and building efficiency, there is a greater need for secure data collection and storage to remain compliant with regulating bodies and ensure sufficient management of each batch is being adhered to.

Eurotherm’s range of data acquisition tools remain consistent with industry standards and compliance regulating bodies.

Products in this range:

Finding the right PLC or PID control system can make all the difference in creating a standardised product from your process, from beneifting you with reducing costs on resource wastage, consistent quality and secure data storage for compliance. The ADM Team here is to help identify which PLC or PID control system would suit your application. Call 1300 236 467 or send the ADM team a message here.