Zero & Span Adjustment of ESI Pressure Transmitters

In this article we dicuss what is meant by 'zero offset' and 'span' and how they can be adjusted on an ESI pressure transmitter.

What is Zero Offset?

ESI’s pressure transducers and transmitters are factory calibrated to read a fixed output range. For Example: A 0 to 10barg transmitter with a 4-20mA signal output, where 0barg =4mA and 10barg = 20mA.

Zero Offset is the amount of deviation in output at the lowest point of the measurement range. Example: your sensor is indicating 0.01 bar, when you know it should be exactly Zero due to the process conditions.

Unlike many pressure transmitters on the market, ESI pressure transmitters can be adjusted when installed by using the adjustment screw located under the transmitter’s connector.

Why would you need to adjust the Zero Offset?

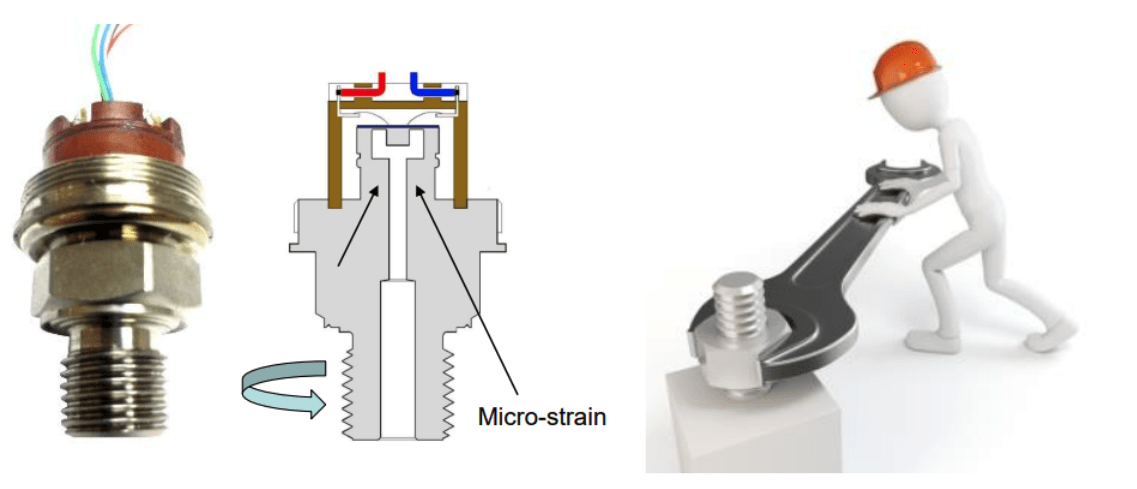

In addition to manufacturing tolerances, the effects of tightening when installing a pressure transducer or transmitter can affect the output reading.

Tightening is obviously necessary to make an effective pressure seal. However, this can induce stress to the housing which may transfer to the sensor and create a small zero offset.

Often this small offset can be corrected in the software/control system/data logger. However, the zero offset can also be carefully corrected with the adjusting screw that ESI pressure transmitters have, which is very convenient.

Other probable causes for the Zero value to be offset include:

- Temperature effects

- Positioning of the unit – orientation. Units with specialised adaptors or filled barrier seals such as the flush diaphragm sensors. This fill oil will affect the pressure very slightly based on orientation, due to gravity.

How to Adjust the Zero Offset on ESI pressure Transmitters

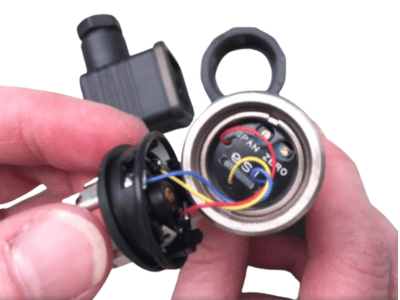

Remove DIN Socket and then remove DIN retaining nut.

Carefully remove DIN plug taking care not to stress coloured wires.

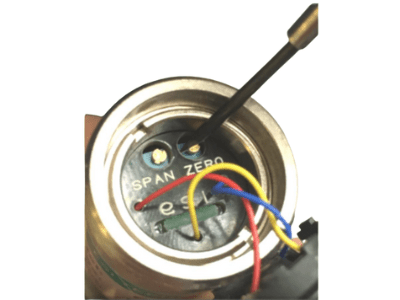

Use the 'ZERO' potentiometer to adjust the setting. Anticlockwise reduces the value and clockwise increases it.

Important: Adjustment of zero offset point does not mean a change in calibration!

Span adjustment – Is it necessary?

Under normal circumstances it is NOT necessary to adjust the Span setting and ESI does not promote the use of Span adjustment.

It should only be used when a certified pressure measurement source is available to use as a comparison standard.

Span is factory set and pre-calibrated to a specific range. Do not adjust the span without good reason, and ensure you have calibrated pressure source at hand for comparison.

Do not adjust Span without firstly checking / setting Zero.

The typical adjustment range available is +/-5% for both Zero and Span (independent).

Span adjustment – When would you use it?

Normally Span adjustment is used to set full scale signal output to a new full scale pressure range.

For example, you may wish to set the GS4200 0-10 bar 4-20mA transmitter to 0-150psi, where 150psi = 10.34 bar.

It is possible to adjust the span setting to 20mA when 150psi is applied usng the following method:

- Firstly, ensure zero = 4.00mA, adjust if required.

- Increase pressure to 150psi (10.34 bar) using calibrated pressure source.

- The signal output will increase to approximately 20.54mA.

- Adjust the Span potentiometer until the electrical output reduces to 20.00mA

ESI Pressure Transmitters with Zero and Span Adjustment Facility

Series | Type |

|

|---|---|---|

| General Purpose |

Image

| |

| HP1000 | High Pressure |

Image

|

| LP1000 | Low Pressure |

Image

|

| PR3800 / PR3850 | Flush Diaphragm |

Image

|

| PR3202 | Differential |

Image

|

| PR3200 | Differential |

Image

|

Please do not hesitate to contact ADM Instrument Engineering for further information on ESI’s range of pressure transmitters.