Ultrasonic Flowmeters and Safe Operations of Slurry Ore Pipelines

Mining operations have been known to employ slurry mixture pipelines to transport ore over long distances.. This method reduces cost of vehicle transport, particularly in remote locations. For mining operations using slurry pipelines, measuring flow is an integral indicator for monitoring production. More importantly, measuring flow is important to understand stress factors on your pipeline.

Using Flow Meters to Monitor Pipeline Stability

Irregular or sporadic changes in flow on slurry pipelines can affect the pipe integrity and footings for the pipe over great distances. Damage to these pipes can have disastrous effects on both human and environmental health.

Inline flow meters can be used for this application. However, these can be costly in terms of the maintenance they require, particularly given the debris-laden nature of the liquid they measure, furthermore putting your pipeline at risk.

Benefits of Ultrasonic Doppler Flowmeters

The Pulsar Measurement Ultrasonic Doppler Flowmeter is a non-invasive solution for measuring flow of your slurry ore pipeline. These systems can be deployed quickly and consistently in field at multiple checkpoints of your pipeline, for both temporary and permanent monitoring.

How does Doppler work?

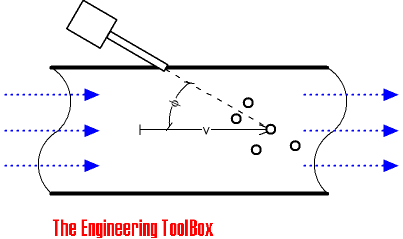

The Pulsar Measurement Doppler Flowmeters consist of two units, a control module, and a transmitter/receiver sensor. An engineer simply clamps the transmitter/receiver to the pipe, where it produces a signal going through the pipe wall and emitting the signal into the solute or gas within the pipe.

The transmitted signal reflects an echo from suspended matter and particulates within the transported liquid back to the receiver, which shows a frequency shift proportional to flow velocity.

The flow meter will perform this function constantly to produce a consistent rate of flow for the field engineer.

Would you like to know more?

If you would like to learn more about how the Pulsar Measurement Ultrasonic Doppler range can be used with your operation, contact the ADM Sense Team today!