Remote and Wireless Monitoring of Industrial Sensors in Hard-to-Reach Areas

Monitoring individual equipment in massive industrial spaces or those hard-to-reach locations can be a tedious and time-consuming process that may involve numerous man hours to complete. These industries include agricultural sites, mining facilities, environmental monitoring, and construction.

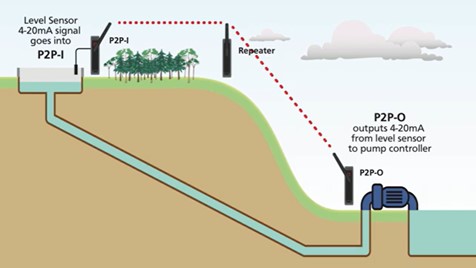

You may need to track sensors from reservoirs, water tanks or mobile moving machineries to ensure they are fully functioning as intended, but being physically present onsite may not always be possible. This kind of job is what Twin Link point-to-point (P2P) wireless system is built for.

If this sounds familiar, contact ADM so we can help you figure out if Twin Link P2P is suitable for your application.

Advantages of Wireless Applications in Industrial Sites

For most industrial locations, hard wiring a tech device may not be feasible and practical. Whether hanging on poles, digging concrete or trenches, long wires equate to complex and costly installations.

Twin Link P2P eliminates wiring all together with the receiver and transmitter pair for distances of up to 4Km – longer if you use repeaters.

What is Twin Link P2P?

Define Instrument’s Twin Link P2P is a wireless gateway that can relay signals over a distance within line-of-sight for remote control and communications. This device can accept up to two inputs and from all types of analogue signals (e.g., 4-20 mA) from point A to point B. See illustration below for reference.

Twin Link can do basic controls, such as switching a pump on or off remotely to regulate levels. It also comes with a basic controller that can do this for you automatically, if required.

For indoor applications, Twin Link gateway is suitable for use within a range of about 90m to 150m through typical buildings and building materials (concrete, brick, etc.) and can send and receive signals from a few rooms away or up a floor or two.

Difference Between Analogue and Digital Signal

Analogue signal is a type of signal that represents a continuous range of real-world values like sound, light, temperature, and pressure. These waves can vary in amplitude and frequency or both over time. Some examples of analogue signals include radio waves, sound waves, and television waves.

Digital signal, in contrast, is a type of continuous signal consisting of just two values 1 and 0 (discrete values) where 1 represents “on” and 0 represents “off”. In computer systems any waveform that switches between two voltage levels representing these values (Boolean) is called a digital signal.

Analogue signals are favoured in applications involving sensors (temperature, pressure, etc.) and some communications and medical equipment since they are easier to process, and they use less bandwidth.

Features of Twin Link P2P

- Wireless and out-of-the-box ready for 4-20 mA I/O (Input/Output applications) – comes with a pair of transmitter and receiver.

- Can accept a variety of input types including mA, RTD and frequency.

- 2 analogue inputs plus 4 digital I/O switches.

- Channels are fully isolated, and units are suitable for industrial environments.

- Transmits through walls - will transmit signals through stud walls, brick, and concrete.

- Easy to setup - Twin Link connects to a PC via USB, cutting configuration time to 60 seconds.

Do you need more information? Contact our team for technical assistance and advice.