Liquid Level Measurement in Industrial and Process Applications

Many industrial and process control applications involve the monitoring of the level of a liquid in a vessel, or storage tank.

There are several methods that you could use to measure or monitor liquid levels. Not all measurement methods are suitable for every application, each has its own pros and cons.

Ultrasonic Liquid Level Measurement

A non-invasive solution often used for measuring level in applications where media remains untouched for corrosive media or hygienic needs, ultrasonic sound reflecting technology is utilised for top access applications.

Pulsar Measurement has pioneered ultrasonic technology with continuous innovations, whereas many other manufacturers retain technology first developed several decades ago, many experiencing outdated challenges such as returned ultrasonic signal interference.

Notably, ultrasonic level sensors are best used in applications that don't produce foam, excessive moisture and a high range of temperature variance can occur, as the sensor can be impacted producing inaccurate readings. Furthermore, ultrasonic signals are emitted through a cone-shaped signal path, which often means the signal may detect vessel walls and obstacles at lower levels, also giving false readings.

Pulsar Measurement Level sensors have overcome submerged obstacle challenges with the use of clever and innovative firmware and setup software, allowing the device to filter out or ignore specific returned signals, greatly improving reliability regardless of application.

Pulsar Measurement provides users with a complete out-of-the-box solution, including a sensor and programmable control panel, negating the need for a separate PLC/HMI cabinet to be built installed or programmed, however, these control panels can be implemented as a part of an installation's wider monitoring and control setup.

Ultrasonic Level sensors can be used for a variety of liquid and semi-liquid state-level measurement applications but can also be reliably deployed on solid media or bulk material applications, such as grains or powder.

Visit the ADM Ultrasonic Level Measurement range here.

Radar Level Measurement

Radar level measurement technology is another non-contact level measurement solution, that uses the reflection of radio microwaves instead of an ultrasonic sound signal.

Radar is normally considered the expensive alternative for troublesome applications that ultrasonic-level sensors may find too difficult to achieve good results. Radar level measurement is more suitable for applications with foaming & strong turbulence or with high temperature and moisture such as molten steel, where ultrasonic would simply not work.

Pulsar Measurements have however recently developed the Reflect Series of radar level sensors that have a cost efficiency that rivals the cost of ultrasonic level sensors, and it is thought that in years to come, radar may displace the use of ultrasonic sensors.

Visit the ADM RADAR Level Measurement range here.

Pulsar Measurement

Pulsar Measurement ultrasonic and radar level sensors are also widely used in sewerage applications in Australia and around the world.

Due to the high presence of methane and other explosive gases in these applications, the original design specification for all Pulsar ultrasonic and radar level sensors includes ATEX and IECEx certification testing.

Hydrostatic Liquid Level Measurement

One of the most common methods of liquid measurement is Hydrostatic Level Measurement. It has a proven track record of being an accurate and reliable measurement method in many applications.

A hydrostatic sensor is the device of choice when access is only available from the top entry of a vessel, making for an easy installation.

A standard pressure transducer with a threaded process connection could be used to measure pressure as a representation of level. This would be mounted outside at the bottom of the vessel (if a process fitting is available), or in the exiting pipework before any shut-off valve.

The advantage of a hydrostatic level measurement sensor is that it can be installed without having to disturb or adapt the vessel. The sensor is easily retracted for cleaning and maintenance purposes and is a highly reliable and robust solution.

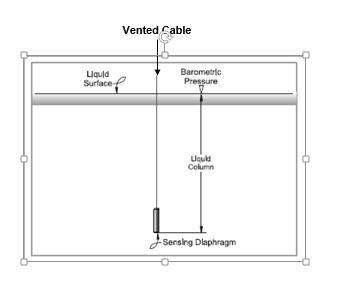

Hydrostatic level sensors monitor the atmospheric pressure to which the liquid is being subjected. The sensor has a permanently fitted vented cable and is suspended in the liquid being monitored, with the sensor as close to the bottom of the tank or vessel as possible, as shown in the diagram below:

The liquid column above the pressure sensor creates a hydrostatic pressure which is a direct indicator for the liquid level.

As the level of liquid drops, the hydrostatic pressure reduces. The sensor converts the pressure reading into an electrical output, which can be used by a PLC, controller, or display.

The sensor needs to be calibrated according to the liquid being measured. For example, water, diesel, cooking oil, etc. all of which have a different specific gravity, meaning there would be a different pressure reading for each media at the same depth.

Compensation for barometric pressure change is achieved via the vented cable.

A vented cable is required because it is important that the sensor element is subjected to the same atmospheric pressure as that acting on the liquid.

This is particularly important for the measurement of low levels of liquid, where changes in barometric pressure can significantly affect the true reading of level.

Hydrostatic level sensors, also sometimes referred to as Deep Well Probes, are very often used in borehole applications, where the water depth in the borehole needs to measure. Boreholes do not always have a wide diameter, which is why a hydrostatic (deep well probe) sensor with a narrow body is preferable.

Sensors can be supplied with up to 500m continuous lengths of cable.

Hazardous Areas

If the liquid being measured is in a potentially explosive area, then hydrostatic level sensors are available that are IECEx certified.

ADM Instrument Engineering has many years of experience of providing hydrostatic level measurement solutions and stocks ESI Hydrostatic level sensors. ESI is a British manufacturer of high quality, high precision sensors.

Other Liquid Level Measurement Technologies

There are several other technologies available that also measure the level of liquids in storage or environmental situations.

Liquid Level Measurement using Capacitance Proximity Sensors

Capacitance sensors measure the conductivity of the medium present. It is suitable for liquids, solids and slurries at high temperatures. Is not affected by top vacuum pressure. Its use can be restricted in deep level measurement applications. It needs to be calibrated or tuned to media type, and the vessel or storage tank needs to be drained and modified with tank wells fitted. Capacitive level sensors are useful for measuring liquids that have a depositing nature (of a certain degree), as the sensitivity can be set to detect material at a location beyond the surface of the probe.

Float Liquid Level Measurement

Mechanical and magnetic versions exist. It is suitable for simple on/off switching applications. Its scope is somewhat restricted, especially with viscous media types that can adhere to the mechanical sensing devices and adversely affect their function. Mechanical devices are also more prone to failure than non-mechanical devices.

Complete Liquid Level Measurement / Monitoring Solutions

As well as stocking hydrostatic level sensors, ADM also stocks a range of process controllers and combined displays/alarms. This means we can offer you a complete liquid level monitoring solution. This applies whether your application is being integrated into a higher-level control system or is a standalone application.

For assistance on selecting a suitable liquid level measurement, or monitoring solution please contact ADM Instrument Engineering.

IS THIS INFORMATION USEFUL?

If so, why not share it with your peers and colleagues. Simply click on the blue LinkedIn share icon below.