How to Select the Correct Invertek VFD for Your Application

Variable Frequency Drives (VFDs) play a critical role in controlling motor speed and torque, enhancing efficiency, and extending the lifespan of equipment. When selecting an Invertek VFD (Variable Frequency Drive) for your application, it’s important to consider key factors that will ensure the drive meets your operational needs. This article will guide you through the selection criteria, explain why Invertek VFDs are suited for various applications, and provide insights into their specifications and potential uses.

Understand Your Application Requirements

Before choosing a VFD, you need to have a clear understanding of the application’s requirements. This includes:

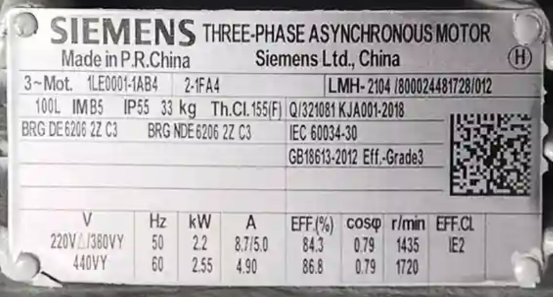

Motor Type and Size: Identify the motor specifications, such as power rating (kW/HP), voltage, and current. Knowing the motor's rated power will help in selecting a VFD that can handle the required load without overheating or overloading.

Load Type: Different applications impose different types of loads. Understanding whether your load is constant torque, variable torque, or has a combination of both will influence the type of VFD you select. For instance:

Constant torque loads: (e.g., conveyors, compressors, extruders) require a VFD with steady power output across a range of speeds.

Variable torque loads: (e.g., fans, pumps) benefit from a VFD that adjusts power output based on demand, improving energy efficiency.

Control Requirements: Determine if your application needs simple speed control or more advanced functionalities, such as PID control, multi-motor control, or synchronization with other equipment.

Choosing the Right VFD Series

Invertek offers a range of VFD series, each designed to cater to specific application needs. Here’s an overview:

Optidrive E3: A compact and easy-to-use drive, ideal for simple industrial and commercial applications such as pumps, fans, and conveyors. The E3 offers straightforward setup with minimal programming and provides robust performance for general-purpose use.

Optidrive P2: Designed for more demanding applications, the P2 series features advanced motor control, including 3GV vector control, which allows for greater torque control and precision. Suitable for heavy-duty applications, including compressors, mixers, hoists, PID control, and more.

Optidrive Eco: Focused on energy savings, this series is optimised for HVAC and pumping applications. It provides variable torque control, integrated energy-saving features, and functions that cater to fan and pump systems, helping reduce energy consumption.

Key Selection Criteria for Invertek VFDs

When selecting the right Invertek VFD, consider the following factors:

Power Rating (kW/HP): Ensure the VFD can handle the motor’s power requirements. Check the drive’s continuous current rating and compare it with the motor’s full-load current.

Input Voltage Compatibility: Confirm the VFD’s input voltage matches your facility’s power supply (e.g., 230V, 400V, or 690V). Invertek offers drives compatible with single-phase and three-phase power systems.

Overload Capacity: Evaluate the VFD’s overload capacity, which determines how well it can handle short bursts of higher power demand. For applications with occasional high starting torque (e.g., crushers, mixers), choose a VFD with higher overload ratings.

Control Features: Depending on the complexity of your application, you might need additional control features like remote control, built-in PLC, or communication protocols (Modbus, Ethernet/IP, etc.). Invertek drives come with various options to integrate seamlessly into industrial control systems.

Environmental Conditions: Consider the operating environment. Some drives need to operate in harsh conditions, such as high humidity, extreme temperatures, or dusty environments. Invertek VFDs are available in different enclosure ratings (IP20, IP55, IP66) to suit these needs.

Why Choose Invertek VFDs?

Invertek drives are known for their reliability, ease of use, and versatile range, making them suitable for a variety of industrial and commercial applications. Here are a few reasons why they stand out:

Ease of Installation and Setup: Most Invertek drives feature intuitive interfaces and straightforward programming, reducing installation time and making them user-friendly for operators.

Energy Efficiency: The Optidrive Eco and other models come with energy-saving modes that adjust power consumption based on load requirements, helping to lower energy bills.

Built-in Protection Features: Invertek VFDs come with motor protection features, including overload, over-temperature, and short-circuit protection, ensuring safety and durability.

Global Availability and Support: Invertek provides strong technical support and a wide network of distributors, ensuring customers have access to help and replacement parts when needed.

Common Applications of Invertek VFDs

Invertek VFDs are versatile and can be used across a range of industries, including:

HVAC Systems: Energy-efficient control for fans, blowers, and pumps, with features tailored for HVAC applications.

Water Treatment Plants: Pump control for water distribution, treatment processes, and irrigation systems.

Industrial Automation: Conveyor systems, mixers, grinders, and other machinery that require precision speed and torque control.

Material Handling: Elevators, escalators, and hoists, benefiting from the smooth start-stop capabilities of Invertek drives.

Agricultural Equipment: Grain handling, feeding systems, and ventilation fans, where variable speed control optimizes operations and saves energy.

Selecting the correct Invertek VFD for your application involves understanding your motor and load requirements, choosing the appropriate drive series, and considering key specifications like power rating, voltage compatibility, and environmental conditions.

Choosing the right VFD not only improves performance but also optimizes energy consumption and reduces wear and tear on equipment, making it a smart investment for many applications.

Contact ADM here or call 1300 236 467 if you need assistance in selecting an Invertek Variable Speed Drive for your application. As Invertek offers a comprehensive range of VFDs designed to cater to various needs, from simple speed control to more complex automation systems, the technicians at ADM will make the decision making process simple and easy.