How to Reduce Material Wastage in Plastic Production

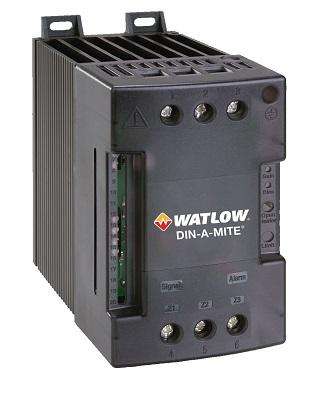

The Watlow DIN-A-MITE range is a series of compact, solid-state thyristors or power controllers designed to regulate electric heating equipment.

Incorporating a Watlow thyristor into your plastics production control system could reduce material waste and improve efficiency.

Using the DIN-A-MITE provides better control of the heater and the process, which will result in precise temperatures, consistently shaped end-products, less wastage resulting from rejects, and reduced downtimes caused by machine failures.

What is a Thyristor?

A thyristor is a type of semiconductor device, which acts like a gate, allowing passage of current in one direction. It can fully turn on or off, resembling a switch, and can control a relatively large amount of power and voltage with a small device, thus making it useful for managing power in various industrial applications, such as plastic production.

Watlow DIN-A-MITE Range

Watlow has four models available under the DIN-A-MITE range: A, B, C and D, that support either single-phase or three-phase operation ranging from 25A to 100A current switching capabilities (depending on the model), and a standard 4-20mA process control.

Each model is a complete setup equipped with silicon-controlled rectifier (SCR), heat sink, wiring and a touch-safe exterior, that is ready for installation.

The DIN-A-MITE range is mercury-free, designed to an equivalent size, amperage specification and footprint as mercury displacement relays (MDRs).

How a DIN-A-MITE Thyristor Reduces Waste and Improves Efficiency

Plastic is a specific type of polymer, and is made from raw materials like crude oil, salt, natural gases, and cellulose, which are refined into ethylene and propylene through a high-heat process called “cracking.”

Forming plastic moulds can be tricky since the procedure requires a specific amount of heat enough to make a mould, but not too much to melt nor deform it.

In plastic processing, DIN-A-MITE is an ideal replacement for MDRs in injection moulding, extrusion, blown film extrusion and blow moulding systems.

DIN-A-MITE is also suitable when longer heater life is required during the process of plastic forming, without worrying about machines automatically shutting down when they reach maximum temperatures. For heavy plastic manufacturing requirements, for example, DIN-A-MITE C three phase/two leg may prove to be a reliable and viable option.

Since DIN-A-MITE models are complete packages with all the components pre-assembled for you, they are easy to integrate with your existing setup, saving you time from having to reconfigure your system again.

Watlow DIN-A-MITE range can be customised after your requirements. Call our team if you need technical advice for your application. Our contact details can be found here.