How to Reduce Costly Unplanned Repairs and Shutdowns with Vibration Sensors

In many industrial settings where a diverse range of machineries perform specialised jobs, manual inspections can be impractical and inefficient, thus, maintenance checks are done on pre-set schedules. While this works in most cases, some hard-working machine components exposed to harsh environments may break before their routine check is up. Industries prone to this plight include manufacturing, railways, mining, pharmaceuticals, construction, and chemical industries.

You may be looking for a remote automated monitoring system that can detect problems early to reduce costs associated with unplanned repairs, delay expensive part replacements, or to simply have predictive maintenance setup in place.

Sensoteq has developed wireless vibration sensing technologies for this purpose, so you can remotely monitor your machines’ health, perform root cause analysis, record and trend data, and help you in your decision-making process.

If you can’t find suitable solutions for your challenging machine issue, contact ADM so we can explain how to implement Sensoteq technologies to your application.

What is Sensoteq Vibration Sensing System?

The vibration sensing technologies – Kappa X, Gateway and Analytix work in tandem to monitor machine health remotely. They can be applied to a wide range of machineries, such as hammer mills, conveyors, mixers, pumps, fans, gearboxes, motors, and more.

This system is built with heavy-duty industrial conditions in mind, so the remote and wireless features come handy for safety, affordability and increased functionality.

Advantages of Wireless Systems

If you consider the environment where this system gets deployed, wireless systems are evidently the more practical option over their hard-wired equivalents.

Wireless systems remove the need for the cabling that is required to connect power and data. For industrial sites of considerable size, this eliminates costs from buying long wires and expensive installation fees.

Depending on how wires extend to reach power outlets, lengthy distance may also cause voltage fluctuations, which can result in poor machine performance and disruptions.

Wires can be a trip hazard, and in industrial zones where employee safety is paramount, having a wireless setup gives you one less thing to worry about.

How does Sensoteq Vibration Sensing System Work?

It is important to note that at the very least, Kappa X sensors and Kappa X Gateway must be deployed together to make it fully functional.

Kappa X is a wireless vibration sensor that monitors rotating equipment and detects faults through irregularities. The data collected by the Kappa X sensors is transmitted to Gateway, which is the communication link between Kappa X sensors and the Analytix software. Analytix is the platform from which you can view data generated by the sensors.

Kappa X Sensor

Kappa X sensor is a battery-operated vibration device that uses 1Ghz frequency suitable for use in harsh industrial environments. 1GHz may not travel as far or as fast compared to its 2.4Ghz, 2.5GHz or Bluetooth counterparts, but it can pass through objects and walls easily, and is less affected by interference.

These sensors use 3.6V1/2AA batteries, which have a life span of about five years, and can be replaced by the user.

Kappa X sensors are equipped with features suitable for rugged environments:

- Wide operating and storage temperatures: -40°C to 85°C

- Shock: 50g

- Rated IP69K

- “Atmospheres Explosibles” (ATEX) versions available – for explosion hazards due to presence of flammable gases or combustible dust mixed in air.

Kappa X Gateway

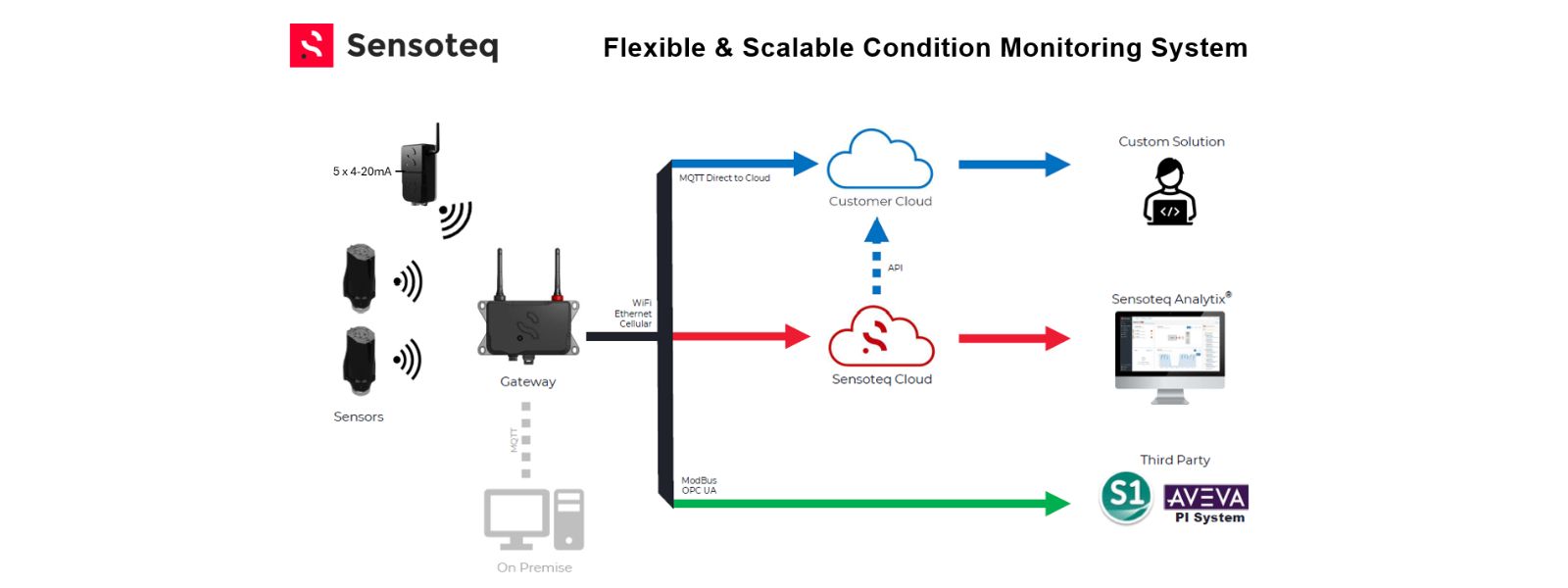

Kappa X Gateway is a communication device that can receive up to 30 remote sensor signals, which it transmits to the Analytix software through Wi-Fi, ethernet, 4G or 5G cellular networks.

A suitable alternative for Analytix is by connecting your Gateway directly to your existing programmable logic computer (PLC) over ModBus TCP/IP if you do not wish to use the Sensoteq cloud software.

Gateway features:

- Wide operating and storage temperatures: -20°C to 85°C

- Shock: 50g

- Rated IP65 (Sealing)

Analytix Software

The Analytix cloud software is the most powerful value-add feature of the whole ecosystem. It allows viewing of current and historical information in the form of graphs, and breaks down data in a simple hierarchy that makes it easier to locate poorly performing or at-risk machines quickly. With proper analysis, this enables predictive maintenance.

The Analytix diagnostic dashboard can also be set to send alarms through text and email messages.

Connect Other Sensors

In addition to the above-mentioned product range, Sensoteq allows standard 4-20mA sensor devices like load cells, displacement sensors, temperature or pressure sensors etc., to be connected wirelessly to its system.

This maximises its value as it allows users to see more data in one location, as well as provide insights on how other variables correlate with changes in vibration.

If you require more information and technical advice, contact our team at ADM at sales@admtech.com.au or 1300 236 467. More contact details can be found here.