EMI and Harmonics in Electrical Systems: Understanding and Mitigating Issues

Electrical systems, whether in industrial, commercial, or residential settings, can encounter issues like Electromagnetic Interference (EMI) and Harmonics. Both can cause significant disruptions, but they originate from different sources and require distinct solutions. In this article, we will explore the differences between EMI and harmonics, how they are caused, and effective strategies to mitigate these problems.

What is EMI?

Electromagnetic Interference (EMI) refers to disruptions in electrical systems caused by external electromagnetic fields. These disturbances can degrade performance, cause malfunctions, or even lead to the failure of electronic devices. EMI is common in environments with a high concentration of electronic equipment, such as factories, data centers, and offices.

Causes of EMI:

Electromagnetic fields: EMI arises from electromagnetic waves emitted by electronic devices, cables, motors, and other components.

Switching devices: Rapidly switching devices, like variable frequency drives (VFDs), power supplies, and relays, generate high-frequency signals that interfere with nearby equipment.

External sources: Radio transmitters, mobile phones, and even natural events like lightning can cause EMI.

What are Harmonics?

Harmonics are a form of electrical distortion that occurs when the normal sinusoidal wave of voltage or current is disrupted. This leads to frequencies that are multiples of the fundamental frequency (usually 50 Hz or 60 Hz), causing issues like overheating, increased energy losses, and equipment malfunctions. Harmonics are especially problematic in systems with non-linear loads, such as computers, LED lighting, and electronic ballasts.

Causes of Harmonics:

Non-linear loads: Devices like computers, printers, and electronic drives draw power in a non-linear manner, creating harmonic distortion.

Power electronics: Inverters, uninterruptible power supplies (UPS), and VFDs or VSDs introduce harmonics into the system.

Transformers and motors: Overloaded or improperly sized transformers and motors may also contribute to harmonic generation.

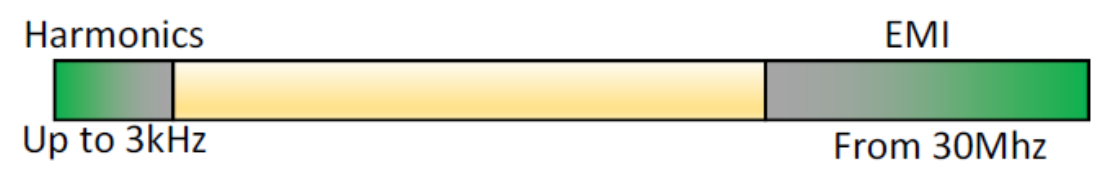

Differences Between EMI and Harmonics

Aspect | EMI | Harmonics |

Nature | Disruptive electromagnetic waves interfering with electronic signals | Distortion in the electrical waveform due to non-linear loads |

Causes | External fields, switching devices, radio frequencies | Non-linear loads, power electronics, distorted equipment |

Effects | Equipment malfunction, communication errors, reduced efficiency | Overheating, increased energy loss, equipment degradation |

Frequency | Typically high-frequency interference | Multiples (harmonics) of the fundamental frequency |

How to Mitigate EMI from a Variable Speed Drive

Cable Selection: This is a key element in mitigating EMI in a system. Use of proper cables for different electrical components in a system will allow the cable to be more protected from external electromagnetic waves. This can help protect sensitive equipment from external interference. Some examples are:

For motor cables under 10mm² CSA then 3 symmetrical conductors with an over-all screen/shield are ok

For motor cables 10mm² CSA and larger use cables with 3 symmetrical conductors and 3 symmetrical Protective Earths with an over-all screen/shield

For Signal/Control cables use Twisted Pair cables, preferably with individual screen and an over-all screen

Proper Grounding: Ensure that electrical systems are properly grounded to prevent interference from affecting equipment.

Filtering: EMI filters can be installed on variable speed drives and cables to reduce the amount of electromagnetic noise.

Separation of Equipment: Place sensitive devices away from high-interference equipment to minimize exposure to EMI.

In the user manual of Invertek drives, there is a section detailing installation guidelines that will allow EMI to be mitigated or kept at a minimum. When installing these variable frequency drives it is strongly recommended that these guidelines are followed. Doing so not only will prolong the life of the drive but make the whole system efficient and safe.

How to Mitigate Harmonics from Variable Speed Drive

Install Harmonic Filters: Passive and active harmonic filters can reduce harmonic distortion by filtering out the unwanted frequencies from the electrical supply. These are also known as chokes which are available from ADM. Please contact our team and they will help you source the appropriate filter.

Use Power Factor Correction (PFC) Devices: PFC equipment can help reduce harmonic distortion while improving the efficiency of the system.

Select Appropriate Equipment: Use equipment that is designed to minimise harmonic generation, such as low-harmonic drives or transformers.

Regular Maintenance: Ensure regular maintenance of equipment to detect and address any harmonic-related issues early.

Both EMI and harmonics are significant issues that can disrupt electrical systems, but they stem from different sources and affect systems in unique ways. Understanding their causes and impacts is crucial to implementing the right solutions.

While EMI can often be controlled through shielding, filtering, and proper grounding, harmonics require the use of specialised filters, appropriate equipment selection, and regular maintenance.

Since VSDs have a high frequency component in built into it, they can cause more harmonic distortion than other components in a system. That is why manufacturers like Invertek from Sumitomo has precautions and quality checks so that their drives operate within standards.

For more information, contact ADM here with your enquiry. We provide tailored solutions to help you maintain a stable and efficient electrical environment.