The Effects of Using Long Cables with an Invertek VFD

When working with variable frequency drives (VFDs) such as those produced by Invertek, the distance between the VFD and the motor is an important consideration that can significantly impact system performance and reliability.

Using long motor cables with an VFD introduces specific challenges that, if unaddressed, could degrade the system’s efficiency and longevity. This article will discuss these effects, how they can be minimised, the impact on system performance, and guidance on selecting the best cables.

Effects of Using Long Cables

Long cables between the VFD and motor can lead to several potential issues, including:

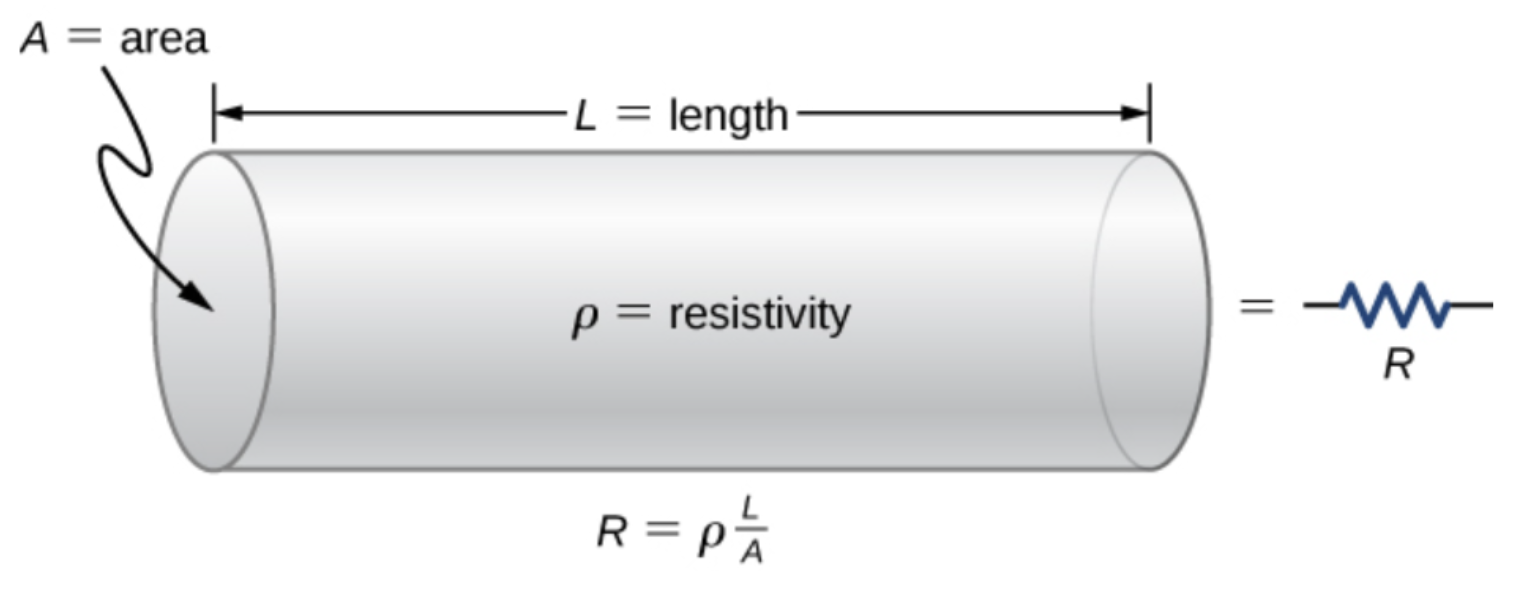

Voltage Drop and Power Loss: As the length of the cable increases, so does the resistance. This can cause voltage drops, resulting in reduced power reaching the motor and diminished performance.

Figure 1: Resistance in a wire is determined by the length of the wire and cross-sectional area. The longer the cable, the higher the resistance. The thicker the cable, more cross-sectional area, the lower the resistance. Reflected Wave Phenomenon: When cables are long, the pulse width modulation (PWM) signals emitted by the VFD can reflect back from the motor, creating high voltage spikes. These spikes can damage the motor insulation over time.

Increased Electromagnetic Interference (EMI): Long cables act as antennas, which can exacerbate EMI issues. This interference can disrupt nearby sensitive equipment and communication systems.

Capacitive Coupling Effects: Long cables possess inherent capacitance, which can lead to additional current flow (capacitive charging current) and increased stress on the VFD output.

Use Output Reactors or Chokes: Installing output reactors or chokes at the VFD output helps limit the rate of voltage rise (dV/dt), reducing the severity of reflected wave spikes.

Minimising the Effects

To mitigate the negative impacts of long cable lengths, consider the following approaches:

Use Output Reactors or Chokes: Installing output reactors or chokes at the VFD output helps limit the rate of voltage rise (dV/dt), reducing the severity of reflected wave spikes.

Install dV/dt Filters or Sinusoidal Filters: These filters can smooth out the PWM waveform, minimising high voltage peaks and reducing the potential for motor insulation damage.

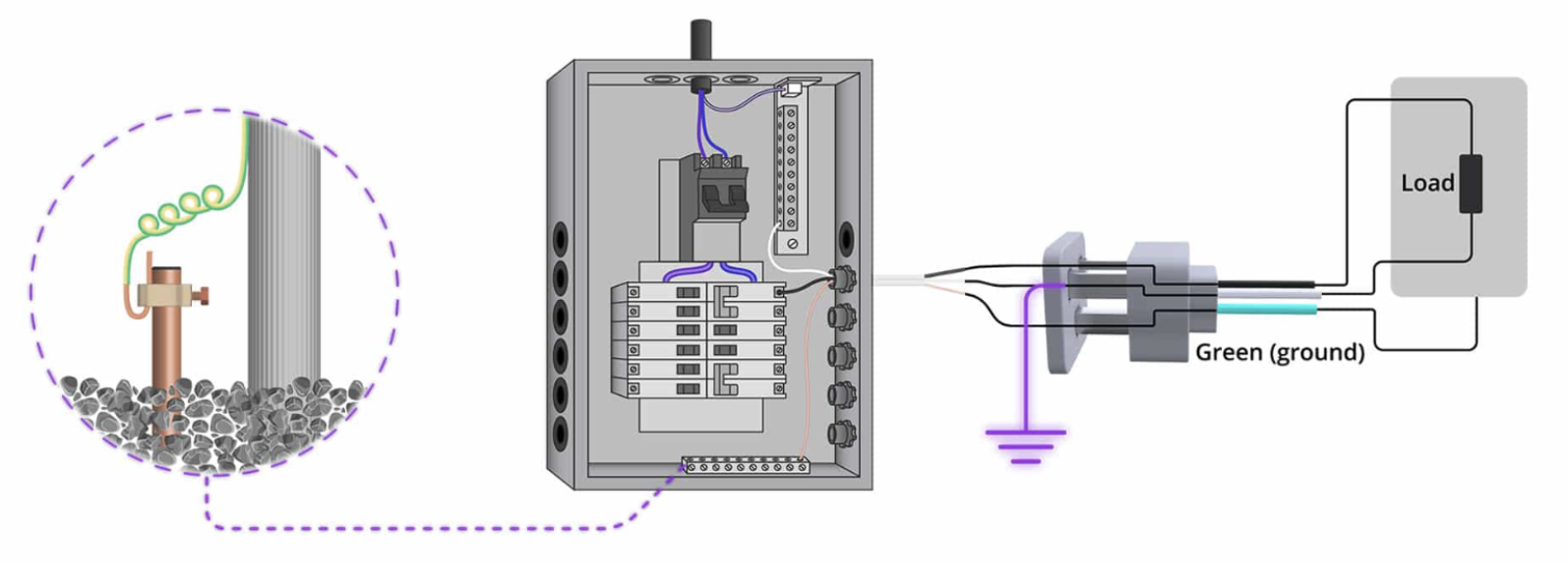

Grounding and Shielding: Properly grounding and using shielded cables can significantly reduce EMI issues. Shielded cables prevent radiated noise and ensure compliance with electromagnetic compatibility (EMC) regulations.

Figure 3: Proper grounding connections needs to be made both inside the cabinet and outside Shorten Cable Length Where Possible: If feasible, minimise the cable length between the VFD and motor to reduce the risk of voltage drops and EMI.

System Performance Impact

Failing to address the effects of long cables can compromise the performance and reliability of the VFD system:

Reduced Motor Efficiency: Voltage drops lead to less efficient motor operation, resulting in energy losses and reduced system output.

Potential Overheating: The additional current flow caused by capacitive coupling can generate heat within the motor, leading to potential overheating.

Insulation Failure: High voltage spikes from reflected waves can weaken the motor’s insulation over time, shortening its lifespan and increasing maintenance costs.

Properly managing long cable lengths ensures that the VFD operates as intended, providing consistent speed control and motor protection.

Cable Selection Guidelines

When selecting cables for use with an Invertek VFD and long runs, consider the following:

Low Capacitance Cables: These cables are specifically designed to minimise the capacitive effects that contribute to additional current flow.

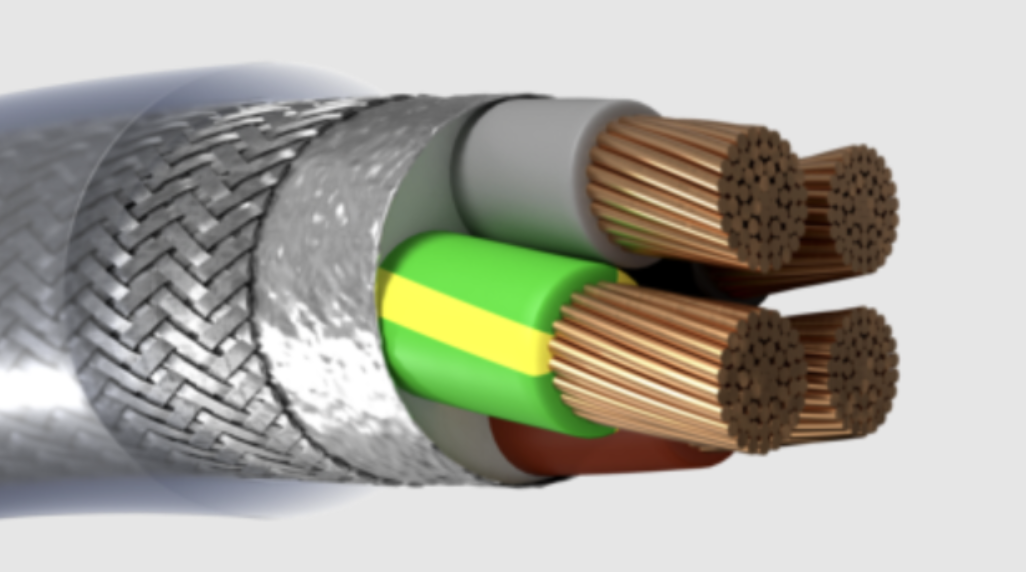

Shielded Cables: Opt for cables with high-quality shielding to reduce EMI and maintain signal integrity.

Figure 4: Proper shielded and insulated motor cable

High-Quality Insulation: Ensure the cable insulation can withstand the peak voltage levels associated with PWM drive outputs.

Appropriate Sizing: Use cables that are appropriately sized to handle the expected current without excessive voltage drop. Consult manufacturer recommendations for guidance.

Long cable lengths between an Invertek VFD and the motor introduce challenges that can affect system performance and longevity. Understanding the effects of voltage drops, reflected waves, EMI, and capacitive coupling is essential. By implementing solutions such as output reactors, dV/dt filters, proper grounding, and selecting the right type of cable, these challenges can be effectively mitigated.

Contact ADM's technicians and we will be happy to explain and solve any issues you might be facing in your system. We would like to ensure these measures are in place to help maintain system performance, enhance motor protection, and support reliable operation over the long term.